What began with the first prototypes in the 1950s has grown into a remarkable success story. Liebherr has played a key role in shaping the development of wheel loaders over the decades—driven by technical excellence, a pioneering spirit, and a forward-looking vision. Explore eleven selected development steps that trace the transformation of Liebherr wheel loaders—from early experimental models to today’s intelligent, high-performance machines.

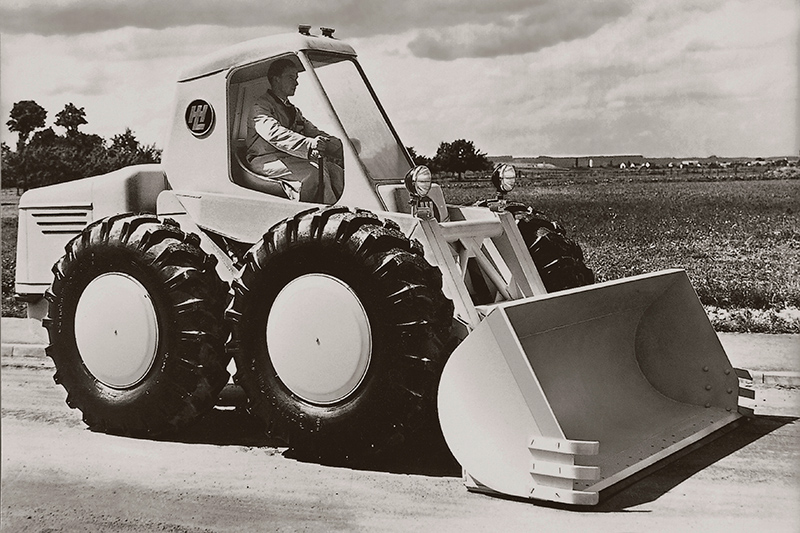

1954: First prototypes – “Elefant” and “Mammut”

In the 1950s, Liebherr took its first bold steps into the world of wheel loaders with the pioneering prototypes “Elefant Type 90” and “Mammut Type 120.” At a time when wheel loaders were still a novel concept, these early machines laid the foundation for a legacy of innovation. Their development marked the beginning of Liebherr’s continuous journey of engineering excellence—a journey that still drives progress today.

1961: LSL 1500 – technology pioneer at the cutting edge

With the LSL 1500, Liebherr introduced a robust and reliable prototype that proved its worth in everyday operation. This pilot series of five “Liebherr Shovel Loaders” (LSL) featured major technical innovations: all-wheel drive, a torque converter, and hydraulic rear-wheel steering. In 2020, the last surviving model was fully restored by apprentices at the Bischofshofen plant.

1974: Two drives put to the test

In pursuit of the most efficient drive system, Hans Liebherr compared two L 531 wheel loaders—one equipped with a hydrostatic drive, the other with a torque converter. Liebherr engineers conducted extensive testing and analysis. The verdict was clear: the hydrostatic drive delivered superior efficiency and economy, ultimately becoming the new standard for Liebherr wheel loaders.

1983: Series production begins – hydrostatic drive sets the standard

After perfecting the technology and ensuring all components performed reliably, Liebherr took a major step forward: the launch of series production for wheel loaders with hydrostatic drive. Production began with the L 531 and L 541 models—manufactured at the time in Kirchdorf an der Iller, Germany.

Late 1980s: Bischofshofen becomes Liebherr’s wheel loader hub

By the end of the 1980s, Liebherr had expanded its wheel loader range and taken a decisive step forward: relocating production to its Austrian site in Bischofshofen. Since then, all aspects of wheel loader development—from engineering and manufacturing to sales—have been centralised there. The site has evolved into more than just a production facility; it is now Liebherr’s international competence centre for wheel loaders.

1994: Stereoloaders – manoeuvrability meets versatility

With their innovative stereo steering—a combination of articulated steering and a steered rear axle—Liebherr’s stereoloaders rank among the most manoeuvrable in their class. Designed for environments where larger machines struggle, they offer exceptional agility. Whether on tight construction sites, in municipal operations, or during winter maintenance, stereoloaders prove to be true all-rounders.

2010: LogHandler XPower – built for the timber industry

With an operating weight of over 37 tonnes and a payload capacity of up to nine tonnes, the LogHandler XPower is a true powerhouse. Its mast, specially engineered for log handling, combined with optimized grapples, enables impressive handling heights of up to seven meters and a reach of nearly four meters—ideal for stacking and loading timber with precision and efficiency.

2015: XPower – two drives, one goal

The power-split XPower travel drive combines the hydrostatic drive with the mechanical drive and offers maximum efficiency. The hydrostatic drive handles short, dynamic loading cycles, while the mechanical drive takes over for long distances or steep gradients. The result: consistently low fuel consumption with full performance, no matter the application.

2023: Electrifyingly good − first battery-electric wheel loader

With the L 507 E, Liebherr brings emission-free performance to the construction site. The battery-powered wheel loader operates quietly, produces zero local emissions and delivers the same power as its conventional counterparts. Thanks to its low noise levels, the L 507 E is perfect for inner-city and noise-sensitive areas.

2024: Clean power – first large wheel loader with hydrogen drive

With the L 566 H, Liebherr takes a bold step into the future. In 2024, the Bischofshofen plant unveiled its first hydrogen-powered large wheel loader prototype—alongside Salzburg’s first hydrogen refueling station. This innovative technology enables emission-free operation without compromising performance, making it ideal for large machines where electric drives reach their limits.

2025: Autonomous travel – no driver needed

At Bauma 2025, Liebherr unveiled its first autonomous wheel loader prototype “Liebherr Autonomous Operations”. Designed for repetitive and monotonous tasks, the system will enable fully driverless operation. By automating routine work, it will free up personnel for more engaging tasks—boosting both job satisfaction and on-site efficiency.

Post a Comment